kill switch on 2 stroke Qualcast 16

I was wondering about fitting a kill switch to my Qualcast 16. If I needed to stop the machine in an emergency I thought this might be quicker than using the throttle. I know some machines do have devices like this fitted. I was thinking that the wire from the points to the coil could be extended up to the handle bar, a switch fitted, and then the wire goes back down again to the coil. Does anyone have any comments to make on this please?

Forums

As Ray (Hillsider) points out

As Ray (Hillsider) points out, all that is needed is a single wire from the magneto to an grounded (earthed) off/on switch on the handle bar . No need for a "return" wire unless there is no continuity through the handlebars to the engine. If there is the "morse code" type cut out switch on the rear of the magneto back plate it's the obvious place to pick up a live connection . If there's no switch the single wire should be taken from the common connection between the condenser and points - no need to break into any existing wire as the "kill" is just achieved by grounding the ignition system, no breaking it.

As far as posting images on this forum goes I think that the kindest summary is " idiosyncratic and variable" !

Well what can I say! here is

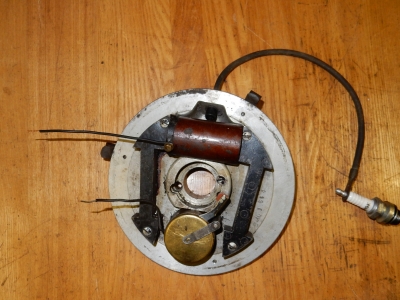

Well what can I say! here is the photo that illustrates the kill switch question I followed the same procedure as earlier but this time bingo.

Now that we have an image of

Now that we have an image of the state of play the easiest way to achieve the objective is to re- join the cut wire and add a third wire running up to a handle mounted off/ on switch. Solder the joint and insulate the junction well with shrink tube or self amalgamating tape and make sure that it can't come into contact with the flywheel . If there's good electrical conductivity from the handle bars back to the engine the other terminal of the switch need just be grounded to one of its clamping screws but if not use twin cable with the ground terminated on a convenient bolt or screw on the engine.

The switch will be closed / "on" to stop and open / " off" to run.

Many thanks for all your

Many thanks for all your advice. It seems quite a simple thing to do.

If I understand the situation correctly by continuing the wire that you mention up to a switch on the handlebars you would I believe have the ability to kill the ignition from the handlebars. Are you thinking of a simple on off switch or do you have in mind a switch that needs to be held in the closed position to allow the engine to run? Alternatively many of the Villiers engines that use this type of magneto have a spring loaded grounding switch mounted on the back of the housing in your photo that looks rather like a small version of a Morse Code key. If this is present on your engine I would be inclined to extend the wire from this switch to the handlebars rather than the wires that you are thinking of.

Can anyone confirm my thoughts?

Re posting photos here many folk seem to have problems I have just tried and failed to copy the image into my posting that you sent to me via email, maybe it is due to this system not liking iPads! I think it was a problem of image size that for whatever reason I could not change.