No Spark

Hi everyone,

I put my Suffolk Colt back together today and tried to start it up but there was no spark. I'm very amateurish with engines so bare with me!

I tested the spark plug on another mower and there was a spark. When holding it on the Suffolk there was nothing. I tried to get into the magneto area to have a look what was going on but I only got as far as the little inspection flap which you take off as I need an impact driver to undo one of the bolts. The plug gap was OK and they were clean, thats about where my knowledge of electrics ends. Once I get inside I'll inspect everything but I presume theres a problem with the coil or condensor? Am I able to buy new ones of these and fit them or do I get a whole new magneto and attach?

Thanks for your help,

Simon

Forums

Thanks for replying, sorry I

Thanks for replying, sorry I did mean points gap. I un-screwed the flywheel nut (clockwise) but there are two more with a large philips head on the edge of the flywheel at around 10 oclock and 2 oclock if you turn it - do I not need to undo these? They aren't labeled on the exploded diagram I looked at.

I do feel out of my depth at the moment but want to learn how to fix this. Once I have the flywheel off what would you be doing next? I need to replace the HT lead because the plastic around the connector which fits onto the spark plug literally crumbled away when I looked at it. Its the original Suffolk plug connector so the wires may this bad.

Other than that, should I be looking at replacing any other bits inside? I don't know how to diagnose any electrical components.

Once again an image will show

Once again an image will show us exactly what generation of magneto you have. Assuming that the points are truly clean it is then a matter of testing and tracking down the culprit . The original pattern plug connector just screws into the end of the HT lead and may be replaced without tools - and is readily available .

I will take a photo tomorrow,

I will take a photo tomorrow, I've just been outside to try something as it was playing on my mind and have a bit of progress....

I stripped a little of the HT lead at spark plug end so that the copper wire was exposed. Then I held it a few millimeters from the metal casing. I had a pretty good spark!

I wrapped the copper wire around the spark plug and held that a few millimeters from some metal - again it sparked but not as strong and very intermittently.

I then wrapped a paperclip around the copper wire at one end and around the top of the spark plug at the other to give me enough length to screw the spark plug in - and nothing.

So it seems to be producing a spark up to the end of the HT lead, but whenever I try to take it any further problems occur. I suppose this shows that the coil etc. is working though?

I successfully got the

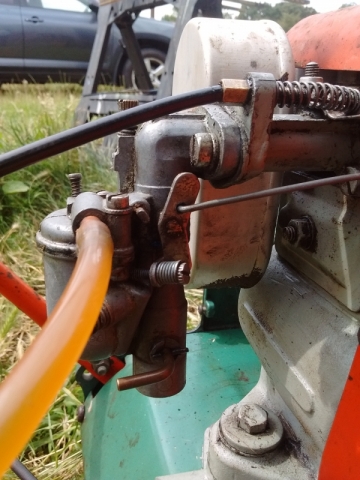

I successfully got the flywheel off! Here's a photo of what was behind it. There was a lot of dust and old whisps of grass all over it which I've dusted off. I need a new HT lead but everything look ok to me. I've cleaned up the points because they were a little dull. They look well used but are nice and bright now.

What should my next move be after a new HT lead and spark plug?

That is a later coil with an

That is a later coil with an encapsulated condenser but as you are getting a healthy spark off the end of the HT lead it would seem that all is well in that department. Sorry to labour the point but make sure that the points are really clean by pulling a strip of clean copy paper through them until there are no black smears on it. When doing this, open points to release the paper before it pulls right through so that they don't grab a few fibres as they snap shut and cause more grief.

My guess is that with a proper plug connector and a new plug you should be ok .

Thanks very much wristpin, I

Thanks very much wristpin, I've cleaned them and a fair bit of dirt came off. They aren't perfectly flat on the ends where they close together but its not too bad. Just a minute little bit of wear. I'll get a spark plug and connector plug and hopefully I'll be further forwards. Can't wait to hear it running for the first time. Is the NGK B6S plug OK?

A B6S will be fine, probably

A B6S will be fine, probably set with. 30 thou out of the box, so shut it down to 25

My parts came today, fitted

My parts came today, fitted them and..... first pull it started! This must be the first time its run in 20 years.

Do you have a picture of the correct throttle linkage with the governor rod? Mine is failing to be very responsive. And when i set it idle the bit the governor rod attaches to fails to fall back to touch the carb. It all feels very loose but the springs look ok. Here's a picture....

The carb end looks okay

The carb end looks okay (apart from not having an airfilter fitted), any chance of removing the airshroud and giving us a picture of the other end ?

As Hortimech says but in the

As Hortimech says but in the meantime just try bending the relay lever ( the one that the cable and governor spring are attached to) slightly downwards at the gov spring end. That is sometimes all that is needed for the throttle to close fully .

Thanks chaps, I'll look at

Thanks chaps, I'll look at bending it tomorrow. The bit on the carb where the governor rod attaches is very loose and wobbly from left to right. Here are two pictures of it in more detail.....

Wobble between the crank and

Wobble between the crank and the throttle spindle is not unusual as the peening on the end of the spindle gets slack. Be careful trying to re-peen the brass shaft as it can be brittle and break away or the shaft can bend. I would solder or braze it but an epoxy such as JB Weld or Araldite may be a safer fix. Restoring a rigid joint between crank and spindle may well resolve the throttle closing issue.

That picture looks very weird

That picture looks very weird, at first glance it looks like two different ones cut in half and then the wrong half's stuck back together, any chance of a better picture ? Just one this time.

Would be good to see a wider

Would be good to see a wider angle image showing both ends of the governor rod in- situ. There were three, perhaps four configurations of rod and your one looks ok for one of them but the " big picture" will clarify the situation.

Sorry for the late response -

Sorry for the late response - I'll get a better photo at the start of the week. The second picture just shows which hole I've got the rod in, I'll stand back and take a wider shot next time.

Not sure whether you are

Not sure whether you are confusing the points gap with the plug gap? With the window in the flywheel at approximately 7 o'clock you should be able to see the contact breaker points. They need to be clean and set to the gap specified - embossed onto the flywheel. Not sure what you need an impact driver for but the flywheel nut is left hand thread - undoes clockwise.