Atco Standard 16" restoration video

All,

I have posted the first in a series of me restoring an Atco Stanadrd 16". This video covers the Engine and Clutch.

Forums

It's possible to embed

It's possible to embed YouTube videos directly on to this site. Simply copy the YouTube embed code (found under the Share link in YouTube) and then paste it onto your page:

- Copy the embed code from YouTube

- Go to your page on this site in normal create or edit mode

- Click on the "Source" button in the editing window

- Paste your embed code

- Click "Source" again to go back to the normal editing screen

- Add any text, images, links etc as per normal posts

- Save the page

Note #1: this embeds an iframe into your page/post. You can change the size by right clicking on the iframe box and selecting "properties" in normal editing mode. Other settings can be changed at YouTube before copying the embed text.

Note #2: if your page already has text or images etc, you can still click on the Source button and paste your embed code at the required position on the page using the same instructions as above.

That was awesome and looking

That was awesome and looking forward to part two.

Thank you very much for this,

Thank you very much for this, it’s very helpful to me and I’m quite sure many others in the future. It's good of you to make the effort and I am also looking forward to future episodes.

But please, slow down a bit so that we can see a little more closely exactly what you’re doing.

I can’t keep up with your frantic pace; I feel quite worn out just watching you!

UTC

Well I have nearly completed

Well I have nearly completed the restoration and have got the mower running. One item on the issues list is the throttle cable which has lost a lot of the plastic sheath and the ferrule and end has been damaged so that it is now too short. Has anybody got a source for replacements or made up their own?

Thanks all.

Once i have sorted some of the issues I will get another video up.

I'm sure in the dim and

I'm sure in the dim and distant past I knocked up a cable sheath from a modern bicycle one, though you might have to check the diameter.

I have a feeling I also soldered an existing ferrule onto a bicycle cable, but I'm damned if I can remember why, and it's no help if it's the ferrule that's cream crackered.

An interesting fact about

An interesting fact about bicycle cable outers (at least to me) is that there are two sorts - gear and brake outer.

Why is this interesting? The brake cable has a spiral wound reinforcement and the gear is much straighter and the brake compresses more easily, and is more flexible, than the brake cable.

So, if you use bicycle outer for a clutch or throttle cable, remember you have a choice - if one doesn't suit, the other may well.

Other definitions of the word "interesting" are available.

I make my own mower and

I make my own mower and motorcycle cables, there are lots of free videos to watch on YouTube concerning this. It's mostly common sense and fairly simple, as a mower dealer I bought inner and outer cable in 25 foot lengths, but beware, they come in metric sizes these days, one way around was buying dozens of bicycle inner made up cables for British bikes, which need much less work, as one end is already done.

Thanks guys, I will get

Thanks guys, I will get trawling eBay for some bits!

Wow, just watched video,

Wow, just watched video, impressive, and inspiring. My standard probably will not go through such a vigerous transformation what with my limited skills, but if its half as good as that I'd be over the moon. Did it run before you started?, or did you know you could fix if it didn't play ball? I only ask as I'm not confident with getting engines working, I've only managed it once and it was probably more luck than judgment , the others were with a bit of outside help from a mechanic. Just wondering if getting something working first is the right course of action before a restoration or sort out issues afterwards, I suppose mechanical and electrical knowledge is a factor, whether the machine will be used or just as a display piece, I'm more for the latter, but the sense of achievement is wonderful when an engine jumps into life, i find a lot of cursing helps once I've pulled the cord and nothing happens. Looking forward to the next vid.

Thanks lee, I did not even

Thanks lee, I did not even bother trying to run it prior to strip as i thought I would cause more damage than good. Despite me having a fair bit of metalworking gear I am no expert on engines. I am very much trying things out, which anybody can do! It is still not behaving as you will see by my next post.

Another plea for help.....

Another plea for help.....

The mower has the typical atco carb found on 16" machines. When I rebuilt it I put the spring below the plunger that the throttle cable connects to. This fitted well, but what is confusing me is that the boden cable has to push this plunger down which seems very strange. Should this spring be above the plunger so that the boden cable pulls against the spring?

An image or two will help.

An image or two will help.

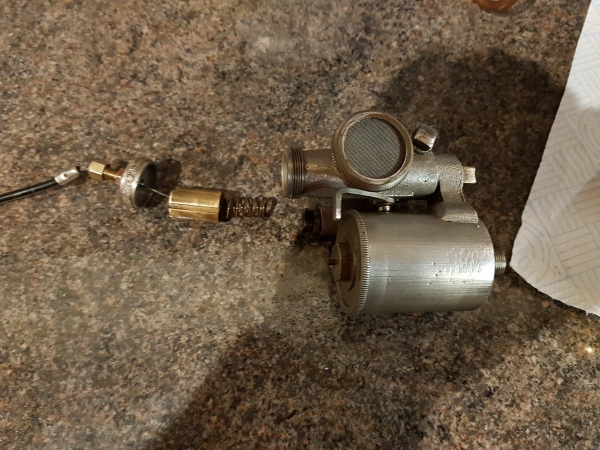

So this is the carb in

So this is the carb in question, atco (senspray?) for a 16" machine

This is how i think the spring should be located, but this does not seem to make sense from the cable perspective as the cable is pushing against the spring (boden cables on really work by pulling, unless the sheath is locked at either end)

This arrangement makes sense from the cable perspective but does not seem to fit correctly in the carb

the question is which is correct?

Thanks in advance!

looking at my own photos I

looking at my own photos I have realised i (think) have the plunger upside down - so the spring should be in the recess but the recess at the top of the carb.

I will go and check this!!!

Well I feel a bit silly now.

Well I feel a bit silly now. I have managed to solve my own problem. The amazing thing is that I got the mower to start with the carb rebuild wrong!

https://youtu.be/q5Hbe3pLhs4

Well I have completed the project and have posted the second video. Hopefully video posting works this time!

Excellent job, love the bit

Excellent job, love the bit where the chicken runs for cover!

Fantastic.

Fantastic.

Brilliant work! Kudos to you

Brilliant work! Kudos to you for recording so much of it on video.

You're fortunate that (especially) the ignition coil and condenser were in working condition.

How was the inside of the fuel tank? Mine was full of varnish from old petroil mix being left in it and I had to do the cocktail shaker routine with water and gravel to clean it out. I may have to use motorcycle petrol tank sealant on it.

Re the grass box, in my case the previous (and original) owner has welded a plate over a large rust hole in roughly the same position as yours. I wish he hadn't done that as it would have been easier to repair it properly had he not.

I stopped work on my Standard quite a while ago due to too many other commitments, but your excellent videos have geed me up to get back onto it.

not sure what I did wrong

not sure what I did wrong with the video link, but here it is below:

https://www.youtube.com/watch?v=pS2FNGVVQ6g