Atco 14/57 chain, bottom blade/cylinder adjustment

Piecing my atco back together slowly and thought I'd check the adjustment set up.

The cylinder has vertical movement but the chain has no tensioner.

The bottom blade bracket pivots, allowing a lot of height adjustment.

The bottom blade also has a pair of fine adjusting bolts with springs.

I assume you move the cylinder to set chain tension, pivot the bottom blade to adjust the gap then use the adjusters to fine tune?

Thanks.

Forums

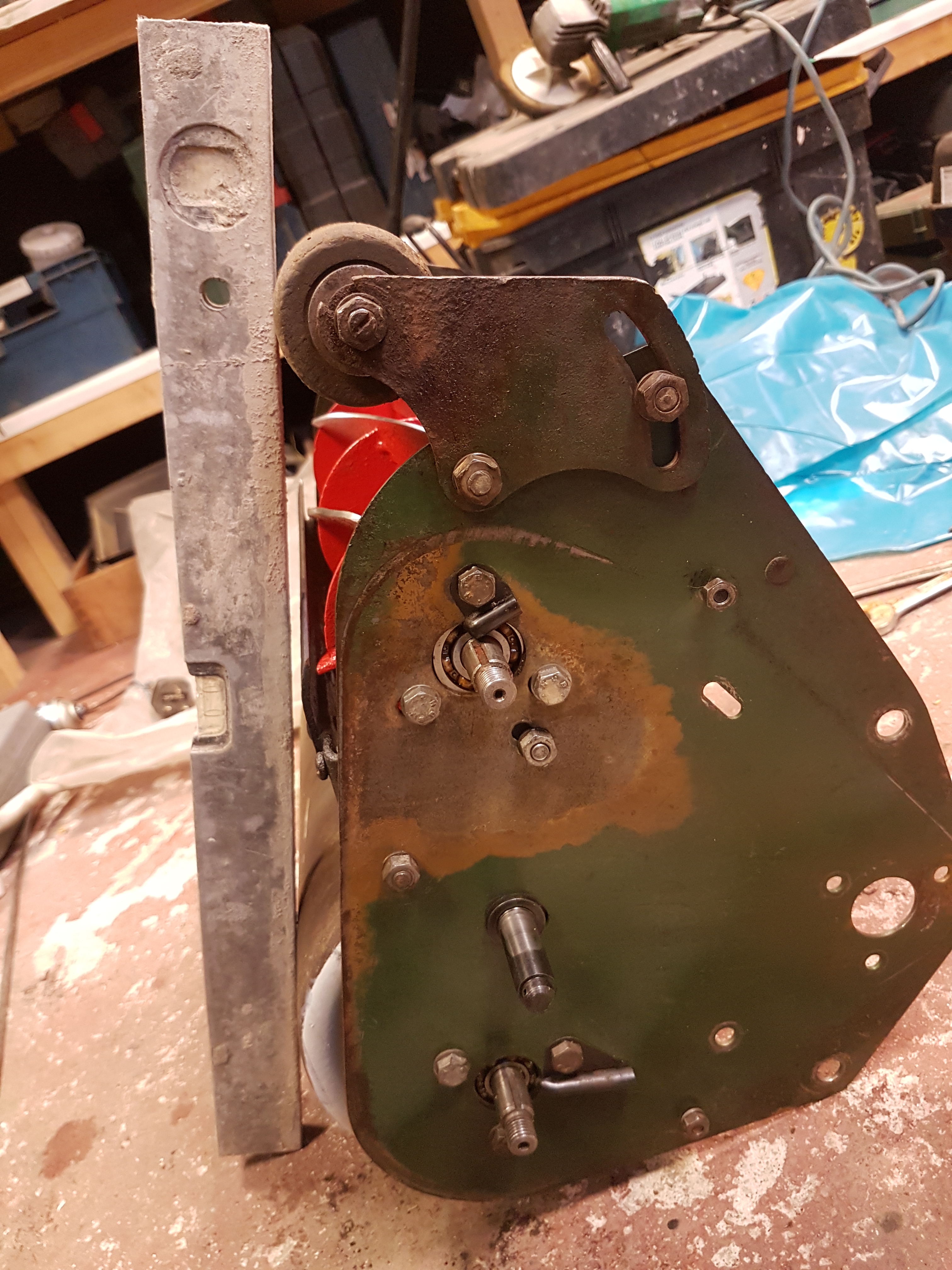

Show is it stood upright

Show is it stood upright with the front roller in place. The chances are that will reveal how the height of cut is altered and set. The screws that move the cylinder to the bottom blade against spring pressure. Any other adjustment may align the cutting cylinder and bottom blade between the rear and front rollers to avoid wedge shaped stripes.

Chain tension may just rely on the correct number of pitches.

Took 3 pics, looking down

Took 3 pics, looking down from the front, underneath so you can see the adjusters and with a level across the bottom with the front rollers set mid way.

None of this has even attempted to be adjusted yet, just putting it back together.

The cylinder is currently

The cylinder is currently fully up. The gap between blade and cylinder is about 5mm. I can still tilt the blade back to meet the cylinder even with the cylinder fully up.

The fine adjusters are currently set as loose as possible.

Even though it's just been reground I still have loads of adjustment.

I'm just not sure if I set bottom blade height, then move cylinder too it, or set chain with the cylinder and move bottom blade up to the cylinder.

I'm surprised the drive chain to the cylinder has no adjustment or slipper to take up slack. I've seen how other atcos do it but there is no mounting hole for one either.

Just noticed this sentence of

Just noticed this sentence of yours...

The screws that move the cylinder to the bottom blade against spring pressure.

There are no screws or springs to move the cylinder. You just have to loosen the 3 bearing mount bolts on each side and slide the cylinder up or down.

The springs only act on the bottom blade.

I find it difficult to

I find it difficult to visualise the set up . An image of those springs in place may clarify it.

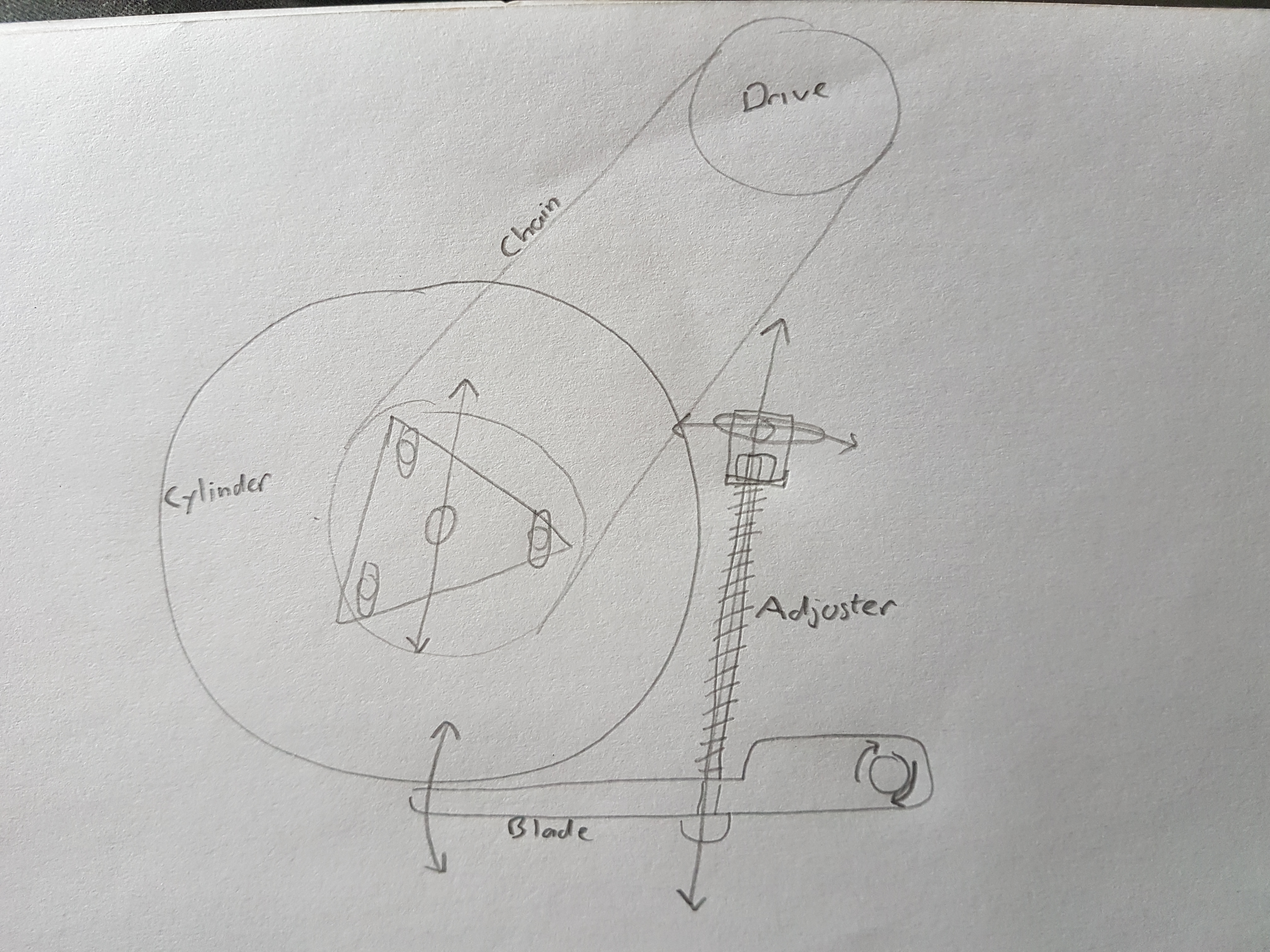

or, even a diagram ?

However if, as your image shows, you are truing the bottom blade to the straight edge across the front and back rollers you are probably nearly there but you need to ensure that the front roller is level with the rear one first.

Here is a quick drawing of

Here is a quick drawing of the parts and the directions in which they adjust.

There is no fine adjustment or springs on the cylinder. It just slides up and down and that movement is the only way to alter chain tension.

Bottom blade can be pivoted to the right area and then fine adjusted with the sprung adjustment screws.

I will make sure the blade is square to the rollers bit I wasn't attempting that in the picture, purely trying to give an idea of bottom blade height with the rollers half way. The bottom blade can come up or down a lot, but the cylinder will have to move with it which has an impact on chain tension.

I won't know where any of these pieces need to be until the chains are on, currently I'm just trying to understand what the adjustment considerations are and maybe what order things should be set in.

If it had a chain tensioner as well then things may be easier, maybe I'll add one, but not keen on drilling new holes.

Fine, I get the picture .

Fine, I get the picture .

The situation seems to be complicated by having two variables - three if one includes the front rollers. I think that the plan of action is first to ensure that the front roller is level with the rear - at any height. I suggest laying a straight edge across the underside of the chassis side members and then another at right angles across it and the rear roller to check that the front roller is level with the back. Releasing the nut on one end of the roller shaft should enable a little independent movement of the roller brackets to achieve this. Then with the shaft nut tightened the whole front roller can be moved to the desired height while remaining in line with the back one.

Having established that the chassis is true to the ground you can then put the straight edge from front to back and level the bottom blade to it. That done you can fiddle the cylinder bearing carriers to achieve the required nip between the moving and fixed blades.

Still leaves the chain, better slightly slack than slightly tight! As Atco didn’t include a tensioner we can only assume that they considered that correct tension could be achieved with out one - perhaps needing a cranked link . ( sometimes incorrectly referred to as a “ half link”)

Thanks.

Thanks.

Once the chains are on and I try setting it up, I'll update this with my results.

If it's not obvious, the

If it's not obvious, the mower is on its back :)

The bolt near the roller is the pivot point for the bottom bracket and the nut moves the adjuster brackets mounting point in the slot.

Cylinder and bottom blade have just been reground.

I also need to move the front oil tube but it seems the wrong 'hand.