An Atco Deluxe(?) with a clutch I've never seen... can anyone help?

Hi There,

I'm a very new member - joined because I have a couple of these Atco mowers and I am started down the road to fully restoring one of them:

I only know they’re Atco’s because that’s what’s printed on the fuel tanks(!), and the cylinder cutters are 14” long because I measured them from end-to-end with a tape measure (I’m assuming that’s how it’s done).

From what I can tell (based on some research in the forums), the one on the left is a 14” Deluxe, lightweight(?), possibly from 1934 (maybe?) – and it has a rather unusual kickstart (I have it ziptied temporarily to the fuel tank support arm) that operates ‘horizontally’ and is real awkward to manage. I replaced the coil on this one, decarbonised and reassembled the motor; cleaned out and rebuilt the carb unit. Replaced the fuel tap with an original refurbished cork tap, and replaced the throttle cable. It runs, but not without some considerable effort! I’m told this one is rare, but I don’t know. That’s where I’m hoping you all come in!

The one on the right is a 14" and I assume is a much more popular or common one that also has a 2-stroke Villiers, and she is a lovely little thing I bought off e-bay from it’s owner’s grandson near Leeds where it was used to mow the local bowler’s green every year for YEARS. Replaced the throttle cable as it was rather worn, and the fuel tap as well because it was leaking. The motor on this one literally ‘loves’ to run; I need only give it one kick of the kickstart (it appears to have a more popular version that kicks downward instead), once I’ve set up the carb and throttle and it fires right up! Amazing!

Both mowers are not without their problems, unfortunately. The Deluxe on the left has a clutch assembly I haven’t been able to find out anything on at all (even here) and appears to be seized up. If I can clean/repair the clutch then that will be half the job. More on that in a moment. The one on the right doesn’t seem to have anything wrong with it at all; however in operation it will often just stop, full stop, when the cylinder cutter suddenly gets real stiff to rotate. If you fuss around with it enough it tends to break loose and rotate freely, then you’re back in business.

The one on the left I have decided to give a proper restoration. I have two fundamental problems facing me right now: the clutch (of course) and the roller barrel in the rear.

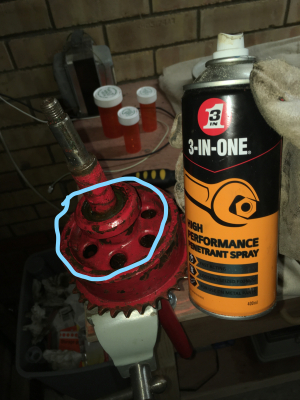

I don’t know quite how the clutch works, only that I can’t seem to get it apart and I’m worried I’ll break something in the process. Here’s how it looks removed from the Deluxe Lightweight:

I’ve been able to break it down to the following, minus the bearings and spring:

I think the part circled comes away from the shaft, I located a plug screw on this part of the clutch and pulled it out, but no such luck. Its been sitting in the vise for a several days now and every time I enter the garage I give it a squirt of penetrant around the joint. After the third day I started to see a small puddle of solvent on the floor so I’m hopeful…

The second part of this dilemma I’m facing has to do with the rear roller:

I (inadvertently) separated one half of the roller from the other half, and now I have NO idea as to how to put this back together, since the ratchet in this half of the roller has to seat between the three dogs on the other half of the roller:

And the dogs in the other half of the roller are spring loaded (understandable) and they interfere with the ratchet, so the two barrels don’t fully seat together. If I can’t figure out how to get these two barrel halves to fully seat then it will be pointless to continue the restoration as I won’t be able to reassemble the mower…

Any help with the clutch and the barrel would be greatly appreciated!

Thanks for your time…

Luftfanatic

Forums

Thanks, Wristpin. I think its

Thanks, Wristpin. I think its a cone. I've never seen this in operation before (I got the motor running after I disconnected the drive chain) which means I don't know which is the stationary side and which is the free side: the sprocket or the collar? I was thinking of hammering it off from behind the sprocket, but I don't know if I would end up shearing something off in the process. I assume you've never seen a clutch like this before? I've blown up the photo a little more this time:

I just don't know which direction to go with this clutch at the moment.

I tried lowering the roller to the pawls, then rotating as you suggested without much luck - I think there's too much interference to coax the pawls away from the dogs enough in order to drop and seat fully.

Ok, it isn't one I have seen,

Ok, it isn't one I have seen, but it is obviously a cup & cone clutch and I would think it will be the cone that is supposed to move. I would remove everything from the cone side of the shaft and then throw it in a drum of diesel for at least a week.

The Atco rollers with the ratchets in the middle can be a pain to reassemble, try fastening the pawls back with stiff wires, something like fine fencing wire and then refit the roller half and pull the wires out, good luck, it usually takes a few attempts.

I'm pretty sure it's a cone

I'm pretty sure it's a cone too so be careful when you get it apart in case you cause any damage to the lining - there won't be a ready supply of replacements for something this old.

If I remember correctly this is a simple friction clutch so everything on the "free" or "moving" side should just slide off once it's loose enough.

You should be able to remove the bearing at the end that attaches to the frame using a puller, if you have one. Then at the very least the spring will come off and you are left with the cone inside the outer shell. It's possible that the cone will come off fairly easily after that. Bear in mind the spring will be very strong because it needs to maintain a strong friction connection to activate the drive. During normal operation the cone will only need to move back off a small amount and that it is activated by a fairly long lever - and even then it can feel quite tight. So at the moment it might feel as if nothing is moving.

When you disassemble, it might be useful to get the paint off the shaft "inside" the spring as this will help everything slide apart.

Keeping taking photos for reference as you proceed. You can never have enough (we have all learned this over the years).

I couldn't find a parts list for this model but I would expect it to reveal a bit more about the components you'd be expecting to find. Maybe someone else has one.

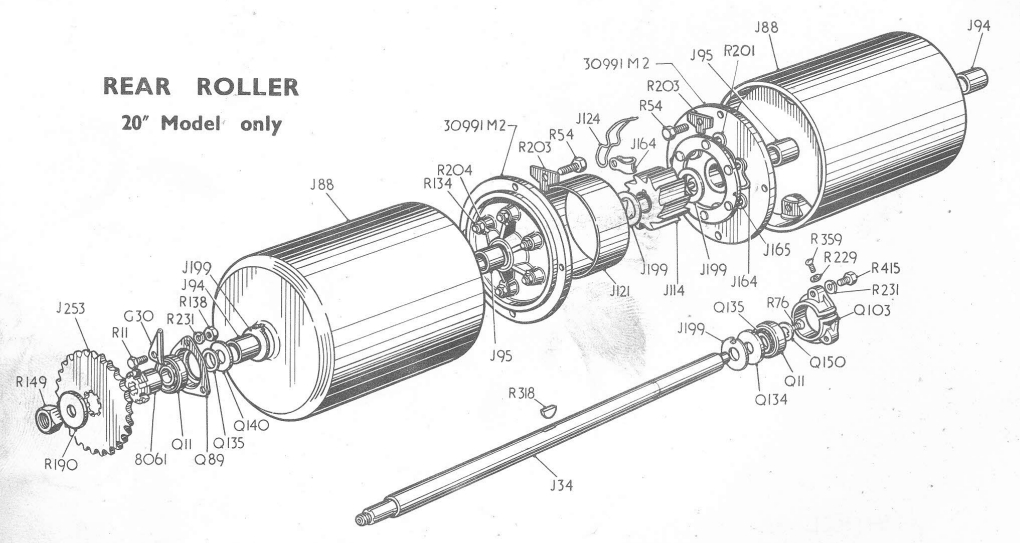

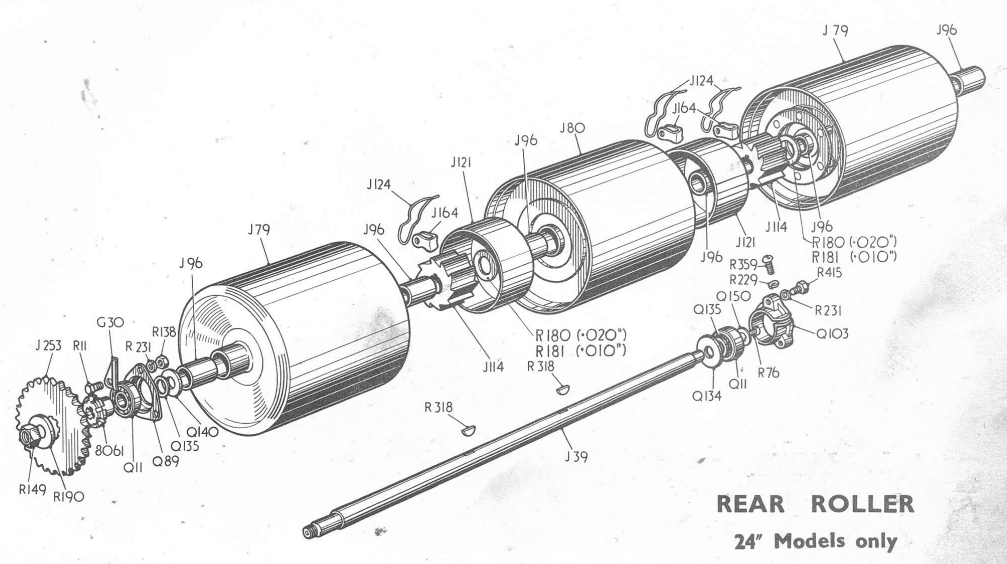

In the meantime, turning to the roller, the images below are from a post war model but it looks like the mechanism is similar to yours (not unexpectedly perhaps). They might help.

I assume you've never seen a

I assume you've never seen a clutch like this before? I've blown up the photo a little more this time:

Seen plenty of cone clutches, both lined and metal to metal, but not that particular application. I'm all for the diesel soak but if its got fabric friction lining I'm wondering if soaking it in diesel may cause problems down the line. That said, metal to metal cones such as on the Atco Grounsdman (men?) can take exception to the soaking treatment as the cast material tends to absorb oil and can be B****r to get free of it later. If it is lined it could be that moisture has rusted metal into the lining material and fused cone and cup together.

Your enlarged image appears to show that the sprocket is positioned on the shaft by a collar that is anchored by a set screw or even a roll pin. The sprocket is probably keyed to the shaft but with the collar (and may be some paint) removed it may be possible to slide the sprocket, cup and cone off away from the withdrawal mechanism.

Excellent drawings, thanks!

Excellent drawings, thanks! I'm surprised I've brought something to the forum no one has seen before (clutch)! So I feel a bit chuffed in the sense I have a rare find here. Let's hope I don't screw it up!

Thanks Hortimech, I'm going

Thanks Hortimech, I'm going to follow your advice here, strip as much of the paint away and keep dousing penetrating oil on the shaft. I've taken a series of videos along the way as a reference to get this mower back together later on after I've painted the parts up. I'm investing in some new self-aligning bearings to attach to the clutch assembly, the cylinder cutter, and the rear roller for when I start the reassembly.

I think I'll be sandblasting

I think I'll be sandblasting whatever parts this clutch assembly breaks down to, and for a friction lining if there is one I'll have to fabricate that I suppose. I'm not even sure what sort of lining I should expect to see in the cone area that I would need to replace, but I'm guessing that it would be the same type of material I would have seen in a clutch a couple years before or after this model.

Speaking of models, years, can anyone confirm for me whether or not this is a 14" Atco Deluxe Lightweight (it has wooden rollers in the front), and the year (more importantly) by chance? I haven't found a data plate anywhere on the machine since I started to disassemble it.

Cheers,

Luftfanatic

A tremendous day of discovery

A tremendous day of discovery!

Tonight after work I decided to give it a go and the penetrating oil apparently paid off - some hammering on a piece of wood against the back of the sprocket shifted the cone-side of the clutch loose, and the entire cup-side of the clutch was soon free to move about/rotate, which means the cone-side is the stationary end:

Armed with that knowledge, I pulled out a shaft puller and hooked it up and pulled it clean off the axle. There's a retaining pin in the cup-side of the axle, which popped out easy enough, and the next step is to separate the axles so as to remove the sprocket-cone and begin giving everything a thorough clean.

I think this is very nearly out altogether.

looking over the cone before putting it in a soak, I noticed some brass pegs embedded in the cone:

then realised they'e holding some sort of lining on to the cone. The previous owner painted this whole thing as one piece, and this is why it was frozen together. I reckon a bit of a soak tonight will clear off all the gunk without ruining the lining.

Thanks for all your advice! Its a bit of a thrill to see something come apart and learning as you go along - like a sort of an adventure, if you will.

Hi

Hi

The Atco in the front you have is a 1934 Atco,they were only made in that year.yes that ratchet start was in a word useless,times many,it would break.The model was called a 14 inch lightweight.Not a deluxe they came later and were distinguished by a steel heavy front roller.The first model to be produced in this style was in 1933 and had a starting handle.The 1935 model which replaced yours had a kick start at the rear which dropped down from a clutch assembly which only came out on what we call a half shaft.

Atco's were prolific producers of many variations on a theme between 1933 and 1939.Its a great shame we don't see more examples

Kind regards

Andrew

Here's an example of the same

Here's an example of the same model...

Thanks, Andrew, it's good to

Thanks, Andrew, it's good to know what I have at last. I found some better photos of her before I started to break her down:

I'm afraid the fellow before me didn't really know what he was doing when he painted it up, because it wasn't a very good job, but you could tell it was in decent shape before then.

Hi OLCAdmin,

Hi OLCAdmin,

Is this one of yours? the ratchet tube on mine is beginning to rust out at the end, I will need to replace it with a box metal one at some point I'm sure. I take it the handles are made of wood. Do you happen to have any close-up picks of the the clutch handle? I took mine apart before I took any photos and its the only thing I don't remember how to reassemble. I wonder if you have the same clutch mechanism I've got?

BTW, i was wrong about the Cup-side of the clutch shaft: in reality it was a retaining ring held in with a pin to keep the clutch cone stationary. Once I started cleaning off the paint and rust that retainer ring slid nicely off the axle, along with the clutch cup, and it was held in place on the other end of the axle with the same sort of retainer ring and pin. So now, the entire clutch assembly has been completely broken down into its components. I am missing, however, a oiler cup lid for one of the bearing ends. It popped out of my fingers while I was trying to clean it out and twanged away on the concrete floor. I can't seem to find one like it on e-bay, does anyone know where I could look? If a picture is needed no problem, I have the other oiler cup lid under lock and key :) so it doesn't escape.

The next subproject will be the rear roller. Now that I have an exploded drawing of how it goes together I think I have an idea how to reassemble.

Clutch. Guessing that the

Clutch. Guessing that the collar engaged by the lever should be free to move; under spring pressure to engage the clutch ( difficult to see but could be either plate or cone) or from action of the lever to disengage it.

Roller. Guess work again. Lower the roller gently until it’s obstructed by the pawls hitting the dogs, and then rotate it slowly against the direction of drive. With a bit of luck the pawls will drop in between the dogs.

Temporary stiffness. Sounds as though a bearing or bush is either running dry or in the case of a ball bearing, lacking in lubrication or bunged up with debris between the balls .