Technical advice needed in restoring Atco Deluxe B17 & B20

Hi,

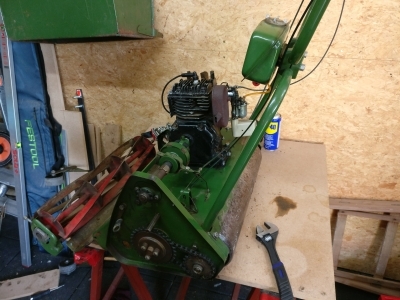

I recently bought 2 atco deluxe mowers ( B17 & B20) and plan on restoring the Deluxe B20. ( No idea how old they are...)

The B17 was meant for spare parts but as it turns out the B17 ( unfortunately without grassbox)

is working even better ( except estetics) than the B20.

So I plan on restoring them both and getting a new grassbox for the 17 inch model

I already started dismantling the B20 and stumbled into some issues.

First thing I want to do is replace the bearings of the cylinder but have no clue on the type. Can anyone give me advice on that?

in regards to the bearing housing. I can dismantle it on the drive side of the cylinder but the non-drive side is really stuck.

Is there a trick you need to know to get the bearing housing off the cylinder.

I also saw that there are links on the forum regarding an instruction manual and spare parts of these machines but the dropbox link is no longer valid.

Is it possible to re- up it of pm me so it is possible to look for the right parts.

Also the roll at the back has bearings and I already read that dismantling it is not without any risk due to the mechanism in there and springs flying around if not done carefully.

Is this one realy worth dismantling and replacing the bearings or not realy necessary? I want to take the risk but any advice here is welcome.

In regards to painting I was wondering if painting it with a 2K spray can does the trick or do I need a paintgun and air to do the work?

How much do you actually need to paint a complete machine?

Can someone also give me advise on the color code for both the body and the cylinder? There are alot

of atco green RAL color codes to find on the web but I would like to use the one most matching the original color?

Thanks in advance for the feedback and help restoring my 2 machines

Forums

Thanks for the quick feedback

Thanks for the quick feedback. As I noticed there is a lot of junk coming of the bearings and the grease seems hard I will put some oil on there, let it rest for a night and see if I can get it off later . So far all attempts were no good.

That is for the bearing house which was on the drive side. The one on the non- drive side does not move at all.

I can assume there is only thread on the drive side where the sprockets are, right?

Have you remove the black

Have you remove the black plastic plug, I seem to remember some of these machines had a securing screw behind the plug

Have you remove the black

Have you remove the black plastic plug, I seem to remember some of these machines had a securing screw behind the plug

I believe that there was a screw, possibly with a left hand thread, on the earlier versions of what became the De Luxe range but on the machines that you have, no screw. A look at the relevant pages of the Dropbox file that I posted shows all the components of the cutter units - the 20" being of identical construction to the 17". Not relevant to your machines but should be noted by anyone using the parts diagram for reference when working on a 14" machine is that there is a spacer on the non drive end that is not used on either the 17 or 20" machines.

In the meanwhile I managed to

In the meanwhile I managed to get the non drive side bearing and housing off.( indeed there was a plastic cover in the end which I removed before)

Unfortunately it came at a price as it was so tight I had to heat up de bearing housing to slide it off and then I had the cylinder with the bearing still attached in my hand.

I then had to cut through the bearing ( was going to replace then anyway ) and I cut a bit of the cylinder because of the grinder I used was larger then the space there was to grind.

The upper part came loose but the inner ring still hooked onto the the cylinder. had to grind that off too and as a result the plastic bearing seal is cut in two and melted because of the heating earlier.

So I today I'm working with some metal filler to fix the grinded parts and will see if I can replace the plastic sealing.

But I was wondering. if I'm planning on replacing them with sealed bearings isn't there something else I can put in between instead of the plastic seal ( if it is not to be saved anymore)?

Thanks for the reply, tips and tricks!

Bearing removal - careful use

Bearing removal - careful use of a couple of tyre levers.

Bearing size / type . RLS4 . These are open without seals but you can used ones with their own seals RLS42RS or RLS4ZZ

Paint. I'l leave that to a greater authority!

Manual / Parts list

https://www.dropbox.com/s/30wx00l0nts3xd0/Atco%20De%20Luxe%20Ownwers%20…