Webb 24" rear roller grip

Hi

Recently restored a 1982 Webb 24", runs beautifully.

The rear roller is split in two and only drives on the left side (near side)

Is this correct? If so can anyone suggest a material to replace the existing tread which is almost polished and provides little grip.

Forums

As Hortimech says a new

I As Hortimech says a new roller section will be hard to come by . The rubber coverings suffered from rough use of the foot brake when the machine was used with a trailer seat. Also the Tecumseh engine used on some models had a nasty habit of dripping fuel onto the right hand roller.

if it's just loss of drive, hopefully it's just stuck pawls and inot broken springs which are no longer available - unless someone has a secret hoard. However, I've heard of successful repairs made by using old recoil starter spring to make replacements.

The good news is that the right hand roller ratchets are the easier ones to get at ; just tip the machine on its side and remove the right hand chassis side plate - lots of bolts to take out but easier than having to drop the roller out to get at the left hand ones.

Thanks chaps, to clarify;-

Thanks chaps, to clarify;-

the rear roller is in two sections of which the left (next to pulley side drive) provides the drive to the left roller. The right roller has no drive and just sits on the spindle in free wheel. This is what it was like when I bought it and I was wondering if this was always the set up. The springs and pawls are there like in the photo supplied by wrist pin but they only drive the left roller.

If there should be drive on the right then I'm missing bits

If the drive is intentionally only on the left roller (to allow for tight turning etc) then I need to re wrap the rollers in a new ribbed rubber material and I can't think if anything suitable to use.

No, they are both supposed to

No, they are both supposed to drive. If you raise the machine off the floor and turn each roller half in a forward direction, it should rotate freely and you should hear the pawls clicking, but if you turn it in a reverse direction, it should turn the shaft.

If there is no drive on one of the roller halfs, you need to investigate why, Wristpin has pointed out that it easy to check the right hand roller, remove the side frame, remove the bearing assy from the roller, remove the cover and found out why there is no drive. Are the springs stuck or broken ? is the ratchet fitted the right way round ? does the ratchet have a key ?

As I said, I cannot think of anything to replace the missing roller rubber, but what ever you use, make sure it is the same thickness as the other roller.

Sorry I cannot be any real help, but I am sure if you examine the ratchet that isn't working, you will find the problem, being able to see what you are repairing helps ;-) If all else fails, drop the entire roller out and compare the side that does drive with the side that doesn't.

Roller rubber. I expect that

Roller rubber. I expect that there are firms who "re-rubber" industrial conveyor belt rollers etc - at a price : but it may pay to spend some time Googling etc. However some years ago I bought several metres of rubber matting for a job that I was doing and Im attaching a couple of images of the bit that I have left. With the careful choice of a modern adhesive you might be able to at least re-rubber the flat area of the roller . Probably wouldn't dress around the outer end like the original but would at least go some way to equalise the diameter. If you go that route it may be wise to cover the joint with a thin strip of steel pop riveted on just to stop the edges lifting. My matting came from a vehicle coach trimmers and body builders - another job for Google!

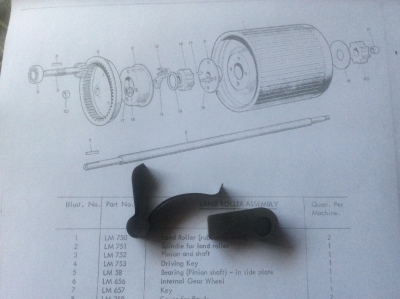

Roller drive. Reading your last post I suspect that you may not quite understand what should happen and what makes it happen. The rollers are supported on a shaft. At the left hand end is a ring gear that is keyed to the shaft (ie the two are locked together and move as one. Then on the outer end of the left roller is a "tin can" inside which there is a toothed ratchet wheel - again keyed to the shaft , Then comes the left roller on the outer end of which are two pawls that engage the ratchet by spring pressure and transmit forward motion. The comes the RH roller with its own springs and pawls engaging another ratchet wheel that is keyed to the shaft and transmitting drive to that roller. There is no connection between the roller halves other than that supplied via the shaft, and the two ratchet assemblies. This allows for some differential action between the rollers so as not to scuff the turf when making tight turns.

Here's the rest of the W24 operator's manual and parts list

https://www.dropbox.com/s/amfv9sza9c541rx/Webb%2024%20owners%20manual00…

https://www.dropbox.com/s/iqqx4gj97cnrzbq/Webb%2024%20Parts%20List0001…

Many thanks

Many thanks

I will use the mower until the of the season then strip it down again.

Your explanations were really useful. When I originally stripped the machine down there was only one ratchet system on the left roller and none on the right. I thought it a little weird.

if I can get it restored back to the original then I doubt I will need to retread the rollers

Cheers

Art

Sounds like a good plan. It's

Sounds like a good plan. It's possible that the studs supporting the pawls, springs and the tin cover worked loose and pulled out leading the previous owner to give up on repairing that roller,so you may have to do a thread repair (Helicoil or similar). Studs are likely to be difficult to find but you can get around that problem by using bolts; it's a bit of a fiddle as you have to install the pawls and springs into the cover with the ratchet wheel and then install it onto the shaft making sure not to displace the key for the ratchet wheel, but it can be done.

If you're looking to collect the parts there are a couple of "wrecker" on W24s eBay at present.

Hi, not sure if I understand

Hi, not sure if I understand correctly, is it not driving correctly because the rubber has come off one half, or is one half not driving at all?

If it is the first, then I am not sure what you can do, the rubber was never available separately and finding a new roller half will be difficult, perhaps the purchase of a used roller/second machine from the well Internet auction site.

If the second, then it may just be the springs stuck, to find out just what the fault is, you will have to remove the rear roller assembly and strip this down.